Gu Taichang: Analysis of key points of man-made panel curtain wall engineering technical specifications

Gu Taichang: Chief editor of man-made panel curtain wall engineering technical specifications, deputy chief engineer of China Building Standard Design and Research Institute, professor-level senior engineer, and first-class registered structural engineer.

1 Definition and scope of application of artificial board curtain wall

1.1 Definition of artificial board curtain wall

Artificial Panel Curtain Wall (Artificial Panel Curtain Wall), that is, the building curtain wall whose panel material is artificial exterior wall panels (except glass, metal and natural stone panels). Including porcelain panel curtain wall, ceramic panel curtain wall, microcrystalline glass curtain wall, stone honeycomb panel curtain wall, high pressure heat curing wood fiber board curtain wall and fiber reinforced cement board curtain wall.

1.2 The scope of application of artificial board curtain wall

The specification applies to non-seismic design and seismic design of civil building porcelain panels, ceramic panels, glass-ceramic panels, stone honeycomb composite panels, high-pressure thermal curing wood fiber panels and fiber cement panels and other artificial panels for external walls with seismic design not greater than 8 degrees. Curtain wall project. The application height of artificial board curtain wall should not exceed 100m.

In view of the characteristics of artificial board curtain wall panel materials and the relatively little engineering experience applied in super high-rise buildings, this code restricts the seismic fortification intensity and application height applicable to artificial board curtain wall engineering. When the application height of the artificial board curtain wall project exceeds the applicable range of this code, it shall be specially designed according to the actual project.

2 Artificial board curtain wall panel material characteristics

2.1 The difference between wood-based panels and wood-based panels for curtain walls

"Man-made panels" curtain walls are not "man-made panels" curtain walls.

The definition of wood-based panels in "Terms of Wood-based Panels and Surface Decorations" (GB/T18259-2000) is: "Use wood or other non-wood plants as raw materials, and after certain mechanical processing is separated into various unit materials, apply or not Plates or molded products glued with adhesives and other additives. Mainly include three types of plywood, particle (particle) board and fiberboard." Wood-based Panel in English, Artificial Panel for Exterior Application in English, and the English translation of artificial panel curtain wall is ArtificialPanelCurtainWall, not Wood-basedPanelCurtainWall.

2.2 Product Standards for Artificial Panels for Curtain Walls

The members of the man-made panel curtain wall specification team have completed the following 5 standards: "Porcelain Panels for Building Curtain Walls" (JG/T217-2007), "High Pressure Thermal Curing Wood Fiberboards for Building Curtain Walls" (JG/T260-2009), "Building Ceramic Board for Curtain Walls (JG/T324-2011), Stone Aluminum Honeycomb Composite Board for Building Decoration (JG/T328-2011), Non-load-bearing Fiber Reinforced Cement Board for Exterior Walls (JG/T396-2012).

The above product standards provide performance data such as sheet bending strength, elastic modulus, Poisson's ratio, water absorption, thermal and moisture expansion coefficient, chemical resistance and pollution resistance required for construction curtain wall engineering applications, and promote these new curtain walls The localization of materials has laid a solid foundation for the compilation of "Man-made Panel Curtain Wall Engineering Technical Specifications".

In addition to the existing building materials industry standard "Glass-ceramics for Building Decoration" (JC/T872-2000), the standard medium-crystal glass is the single-furnace batch self-leveling sintering method used in the early days. At present, glass-ceramics has a new continuous rolling method and new technology and formula system. It is urgent to formulate new glass-ceramics product standards to replace "Glass-ceramics for Building Decoration" (JC/T872-2000) to make glass-ceramics Mechanical properties, surface quality and decorative effects better meet the needs of building curtain walls.

2.3 Burning performance of artificial board curtain wall materials

The materials used in the curtain wall should have a certain fire prevention function to prevent the spread of building fire and reduce the loss caused by fire. However, as a non-load-bearing building exterior wall enclosure structure, the curtain wall must have certain thermal performance to meet the thermal insulation requirements of the building exterior wall. Therefore, the materials used for the curtain wall cannot be all non-combustible materials.

There are many kinds of artificial board curtain wall materials, and there are big differences in materials. Among the six panel materials, there are three types of A, B1 and B2: porcelain plates, ceramic plates, glass-ceramics, and fiber cement boards are Class A non-combustible materials; stone honeycomb composite boards It is a Class B1 flame-retardant material; the common type of high-pressure thermosetting wood fiber board is a Class B2 combustible material, and the flame retardant type is a Class B1 flame-retardant material.

According to the relevant provisions of the "Code for Fire Protection Design of Buildings" (GB50016) that is being revised, taking into account the combustion performance of materials and the rescue height of domestic fire-fighting equipment, this "Code" makes the following specific requirements for the combustion performance of the main materials of the curtain wall:

1) The combustion performance of the curtain wall supporting members and connecting materials should be Class A;

2) The combustion performance of the panel material for curtain wall shall be Class A when the building height is greater than or equal to 50m; when the building height is less than 50m, it shall not be lower than Class B1;

3) The combustion performance grade of the insulation material for curtain wall should be A;

4) The fire-proof sealing material for curtain wall should meet the requirements of the current national standards "Fire-proof sealing material" (GB23864) and "Fire-retardant sealant for construction" (GB/T24267).

3 Classification and structural characteristics of artificial board curtain walls

3.1 open curtain wall, closed curtain wall

Decorative curtain wall with a solid wall behind it, including the following two types of curtain walls:

(1) Open curtain wall: The ventilated exterior wall decoration layer, that is, the joints between the curtain wall panels are not sealed, and they are not airtight and watertight. Including slit type, panel seam shielding type, panel seam overlap type, panel seam molding type. The open decorative layer curtain wall outside the enclosure wall forms a shading and ventilated air compartment, and a small amount of rainwater entering the air compartment is evaporated by the effect of natural ventilation, effectively protecting the wall system behind it.

(2) Enclosed curtain wall: a building curtain wall with air-tight and water-tight performance by adopting sealing measures between the joints of the curtain wall panels. Including glue-injected closed and glue-strip closed curtain walls.

3.2 external wall hanging board

Enclosure type curtain walls without a solid wall behind, including the following two types of enclosed curtain walls.

(1) Single-panel system enclosure system: a closed curtain wall constructed with only one layer of panels, similar to an enclosure glass curtain wall.

(2) External wall panels and wall panels integrated integrated enclosure system: external wall panels, wall panels and their connectors, and thermal insulation and fire protection materials integrated integrated composite external wall system will be high-rise and super high-rise man-made panel curtain wall buildings The development direction of industrialization, such as concrete exterior wall siding, GRC exterior wall siding, etc.

But this specification does not include this content.

4 Performance and structural design characteristics of artificial board curtain wall

4.1 Wind pressure resistance performance

Back-ventilated open man-made panel curtain wall: The relevant test proved that compared with the closed curtain wall, the open curtain wall bears lower wind load. However, due to the influence of various factors such as the shape of the facade, the structural form of the plate seam (butt joint, lap joint), the width of the seam, the length of the seam per unit area, and the lack of test data, a unified reduction factor cannot be given. . When designing the curtain wall, the reduction factor can be determined through wind tunnel model tests according to the actual situation of the project.

4.2 Thermal performance

Open curtain wall with a solid wall behind: The simulation results of computational fluid dynamics CFD software show that when the width of the slab is 10mm and the depth of the cavity is 100mm, the outdoor wind speed of the vertical slab is respectively At 3m/s and 5m/s, the average wind speed in the air interlayer was 0.75m/s and 1.2m/s, respectively, and both reached a good ventilation state. The contribution of the heat transfer resistance of the open curtain wall can be ignored.

Enclosed curtain wall: (refined the relevant provisions of the "Design Standard for Energy Conservation of Public Buildings")

(1) When there is no other wall behind the artificial board curtain wall, the thermal insulation structure system of the curtain wall itself should meet the heat transfer coefficient requirements of the external wall of the building energy-saving design.

(2) When there are other walls behind the artificial board curtain wall, the outer protective structure composed of the curtain wall and the wall shall meet the heat transfer coefficient requirements of the external wall of the building energy-saving design.

Exterior wall system with closed man-made panel curtain wall, according to the "Code for Thermal Design of Civil Buildings" (GB50176), use the stable heat transfer calculation formula to calculate the thermal resistance of the multi-layer enclosure structure.

4.3 Structural design

4.3.1 Panel seam design

(1) Porcelain panels and glass-ceramic curtain walls can adopt closed or open panel seams. Porcelain plates and glass-ceramic plates are homogeneous materials fired at high temperature with low water absorption and good weather resistance. Both open and closed types can be used.

(2) The stone honeycomb panel curtain wall should adopt closed panel seams or open panel seams. The stone aluminum honeycomb panel is a composite material board formed by bonding the stone panel and the aluminum honeycomb panel. Priority should be given to the use of glue-injected closed type, and the open type should be sealed and waterproof.

(3) The ceramic board and fiber cement board curtain wall should adopt open board seams or closed board seams. The water absorption rate of ceramic slabs is relatively high, and open seam design should be preferred. For ceramic slabs with low water absorption rate (close to the lower limit), if the building climate is suitable, closed panel seam design can also be adopted. Fiber cement board is a cement board that contains organic synthetic fiber or cellulose fiber and is cured by high-pressure steam with high water absorption. The open type should be given priority. If the environment is suitable and the board is protected, the closed type can also be used.

(4) The wood fiberboard curtain wall shall adopt open board seams.

Wood fiber board is an organic material containing 70% wood fiber. Due to the natural properties of wood, the board will change with the relative humidity of the environment. Therefore, the wood fiberboard requires high consistency of the ambient temperature and humidity on the front and back of the board, otherwise it is prone to deformation. Therefore, an open seam structure should be adopted to reduce the air pressure difference between the cavity inside the panel and the external environment, and reduce the pressure difference. The rainwater brought into the cavity inside the panel keeps the cavity inside the panel and the outdoor air circulated with each other, and keeps the temperature and humidity environment inside and outside the panel consistent.

4.3.2 Air interlayer structure design

For open curtain walls with back ventilation, the minimum distance between the panel and the outer surface of the back wall should not be less than 20mm, which is based on the German standard "(DIN18516-4-1990) exterior wall decoration. Back ventilation. Single-panel safety glass. Requirements, measurement, It is determined by the requirements of “inspection” that is the minimum requirement for the ventilation space behind the curtain wall panel. In the specific project, the space requirements of the appropriate ventilated room should be determined according to the wind environment where the curtain wall is located and the specific conditions of the panel joint design.

For the design of open curtain wall panel joints, according to the decorative effect of the external wall facade and the ventilation needs of the air interlayer, choose the open seam type with flat butt or the shield type with the overlap of flat and tongue-and-groove panels, and the shield type with inlaid strips. Seam design.

5 Mechanical properties of artificial board curtain wall panel material

5.1 Mechanical properties of a single material panel

5.1.1 Design value of bending strength

The design value of the flexural strength of the panel material is equal to the standard value of the flexural strength (flexural strength) divided by the panel material performance sub-factor. The standard value of bending strength (flexural strength) can be determined according to the performance data of the panel material product standard.

The sub-factor of panel material performance is determined according to the different characteristics of the panel material:

1) Porcelain plates, ceramic plates and glass-ceramics are brittle materials, and the material performance sub-factor is 1.8;

2) The material of fiber cement board is between brittle and ductile materials, and its material performance sub-factor is 1.6;

3) Wood fiberboard is a ductile material, and its material performance coefficient is 1.5.

5.1.2 Design value of shear strength

When porcelain plates, ceramic plates, glass-ceramics and fiber cement boards are supported and connected by short hangers and long hangers respectively, the plates will be subjected to the support reaction force of the hangers at the hanger notches to generate shear stress. Therefore, it is necessary to specify the panel material Design value of shear strength. Since these materials are non-isotropic non-metallic materials, the strength relationship between the shear stress and the normal stress is not suitable for the fourth strength theory, and the method of τ = 0.577σ cannot be directly used to determine the shear strength of the plate. Therefore, the specification compilation team conducted comparative tests on the shear strength and flexural strength of four materials: porcelain plate, ceramic plate, glass-ceramic and fiber cement board, and determined that the quantitative relationship between the shear strength and the flexural strength of the panel material is :Porcelain board 0.5; ceramic board and glass-ceramics 0.2; fiber cement board 0.4.

5.2 Mechanical properties of composite panel

Stone honeycomb panel is made of natural stone sheet and honeycomb panel through adhesive bonding. The thickness of the stone panel is about 5mm, and the total thickness is more than 15mm. It is usually installed by four-point support connection with back-bonded pre-set nuts. The characteristics of the structure of the board-along the thickness direction of the board, it is an asymmetric structure, and the materials are different, and its mechanical properties are different from the general aluminum honeycomb panel and other solid boards. The specification team conducted a special theoretical and experimental research on the mechanical properties of this new type of composite material, and successfully solved this problem.

5.2.1 Standard value of bending stiffness and bending strength of stone honeycomb panel

The limit state bending stress of the stone panel of the stone honeycomb panel when cracks or fracture occurs under bending and tension is used as the bending strength value of the whole plate; the bending stress when the whole plate is bent and yielded is not used as the bending strength value.

(1) Determination of the bending stiffness of the whole plate:

a) Test method: According to the three-point bending method of outhanging beams specified in "Test Method for Bending Performance of Sandwich Structures" (GB/T1456-2005), the maximum load p and the total load when the stone panel of the stone honeycomb panel is cracked or broken is measured. The bending stiffness of the plate D;

B) Calculation method: in accordance with Appendix A of "Stone Honeycomb Composite Panel Stiffness Calculation" of "Man-made Panel Curtain Wall Specification".

(2) Determination of the bending strength of the stone panel: The bending stress of the stone panel is calculated by the following formula.

Where: σ is the bending stress (MPa); p is the maximum load (N); l is the distance between fulcrums (mm); E is the elastic modulus of the stone (MPa); y0 is the distance between the neutral axis and the stone panel (mm) ; D is the bending stiffness of the stone honeycomb panel (N?mm2).

According to the data obtained from the whole plate test and the bending stress value calculated according to the above formula, the standard value of bending strength is obtained by mathematical statistics and other methods.

5.2.2 Design value of bending strength of stone honeycomb panel

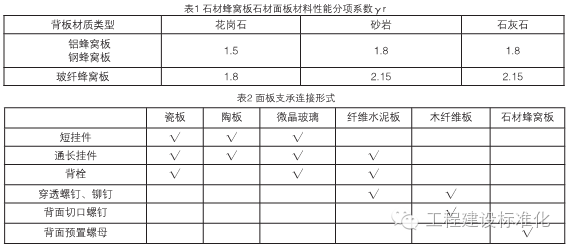

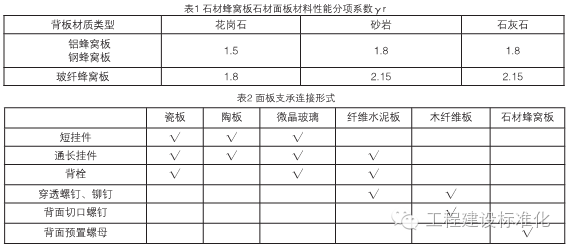

The design value of flexural strength is equal to the standard value fk of the flexural strength of the stone honeycomb panel divided by the sub-factor γr of the material performance of the stone panel. Taking into account the characteristics and engineering experience of different composite board materials and stone panels, the "Man-made Panel Curtain Wall Specification" stipulates the value of the subitem coefficient γr of the material performance of the stone honeycomb panel and stone panel, as shown in Table 1.

6 Artificial board curtain wall panel support connection design

6.1 Panel support connection form

The diversity of panel support and connection forms is another major feature of the man-made panel curtain wall. The six panel materials and the six support connection forms are based on the material characteristics and the bearing capacity verification test of the support connection. The appropriate support connection form for each panel is determined. As shown in table 2.

6.2 The bending design of the panel

The six support connection forms of the six panels, and the stress forms are: 1) point support (four-point support, multi-point support); 2) opposite side support. The finite element method can be used for analysis and calculation, and the commonly used four-point support and opposite side support calculation formulas are given in the code.

The cross-sectional shape of the hollow ceramic slab is quite complicated. The maximum bending stress standard value should be analyzed and calculated by the finite element method, or the uniform static load bending test result can be used, and then divided by the material performance sub-factor of the ceramic slab 1.8 to determine its resistance. Bending capacity.

For the wood fiber board and fiber cement board that are connected through the panel support, the multi-point support connection with more than four points is usually used. The bending moment at the supporting point position is generally smaller than the mid-span bending moment of the four-point support panel, so it exceeds four points. The distance between the four points with the largest spacing can be selected as the calculation span for the connected panels, and the approximate calculation can be carried out by referring to the formula of the four-point supporting panel.

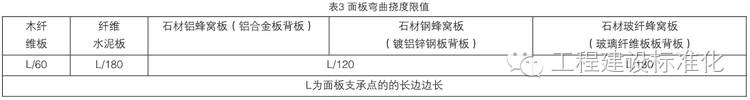

6.3 Panel bending deflection limit

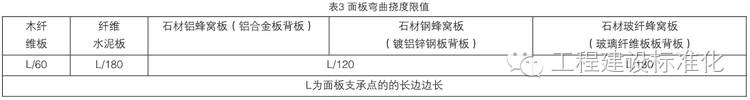

High-pressure heat-cured wood fiberboard: low modulus of elasticity, only 1/8 of glass, but its standard value of bending strength is about twice that of glass. It is a high-strength ductile material that can undergo greater deformation without damage. The bending test of the plate and engineering practice experience determined the deflection limit to be 1/60.

Fiber cement board: The elastic modulus is low, about 1/5 of glass, and its standard value of bending strength is about 1/2.8 of glass, which is a material with low stiffness and strength. According to the results of bending tests on fiber cement boards, the deflection of boards with different thicknesses is 1/60~1/140, which is determined to be 1/180.

Stone honeycomb composite panel: It is a composite panel made of brittle ultra-thin stone panel, aluminum honeycomb core and three different back panels. It has a certain degree of flexibility. According to calculation and verification test results, combined with engineering experience, it is determined as 1/120 and 1/180 respectively.

Porcelain plates, ceramic plates and glass-ceramics are brittle materials with high elastic modulus, and the thickness of the cross-section of the plates is relatively large when used, and the rigidity of the panel is relatively high, so there is no need to control the deflection during bending deformation. Wood fiber board, fiber cement board and backboard material type stone honeycomb composite board is a relatively flexible material, and its deflection during bending deformation must be controlled (Table 3).

6.4 Tensile and shear bearing capacity of panel support connection

6.4.1 Stone honeycomb panel with pre-installed nut point support connection on the back

The special-shaped connecting nut supported on the back of the stone honeycomb panel is preset in the factory with adhesive.

Use connecting bolts to fix on site installation. The standard compilation team conducted a comparative test of tension and shear, which verified the failure form of tension and shear of the bonded pre-set connecting nut and the quantitative relationship between the bearing capacity of the two. The "Specification" stipulates that the tensile bearing capacity and shear bearing capacity of the stone honeycomb panel pre-set nuts should be determined by tests. The design value of the tensile bearing capacity is equal to the measured minimum value of the pre-set nut connection tensile failure force divided by the pre-set nut connection load The force sub-factor is 2.15, and the design value of the shear capacity is not more than 0.5 times the tensile capacity.

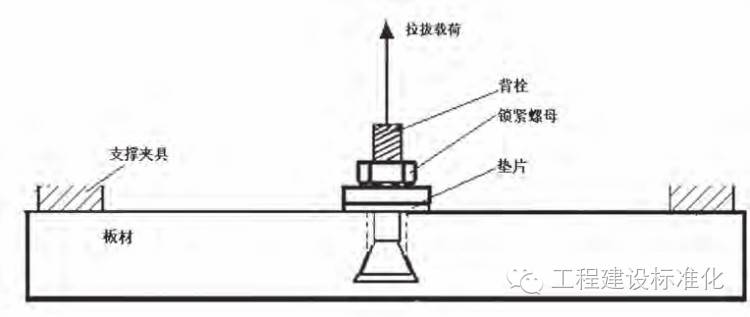

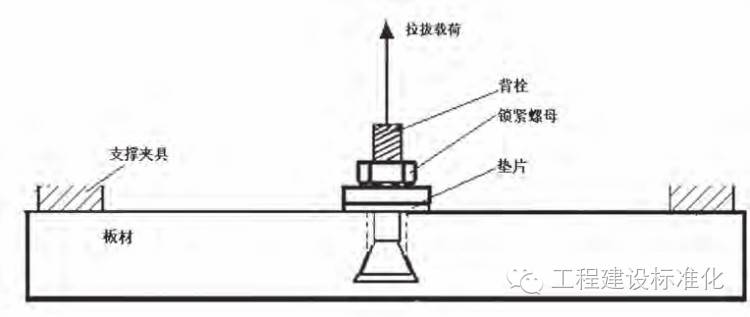

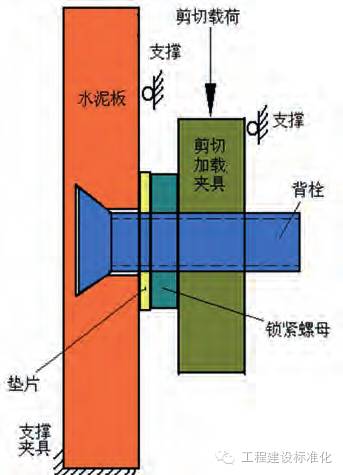

6.4.2 Porcelain plate, glass-ceramic and fiber cement board supporting connection of back bolt belong to local mechanical connection mode. The tensile and shear bearing capacity of back bolt connection is related to the material of panel and back bolt and the difference of back bolt. The variety, specification and structure type, anchoring depth, processing accuracy of the back bolt hole and the assembly quality of the back bolt are closely related to factors such as accurate calculations and can only be determined through experiments.

For the three panels of porcelain plate, glass-ceramics, and fiber cement board, three back bolts with different detailed structures from the three back bolt production units of Fischer, Sailfish and Stay in the standard organization group were used to connect the back bolts. The pull-out and shear load-bearing capacity tests of the Pyramid have verified the failure modes of pull-out and shear and the quantitative relationship between the load-bearing capacities of the two (Figures 1, 2).

the experiment shows:

(1) For fiber cement boards that are between brittle and ductile materials, the back bolts are all cone-shaped failures after the pull-out test. After the shear tests, the back bolts are bent and then accompanied by local failure of the plate where the back bolts are installed.

(2) For relatively thin brittle porcelain plates, the main failure mode of the back bolt pull test is the fracture of the porcelain plate (large and small support spacing), and only a part of the samples are cone-shaped failures. After the shear test, the main failure forms of the porcelain plate are partially broken, the porcelain plate is broken, and the front of the porcelain plate is damaged.

(3) For relatively thick brittle glass-ceramic plates, the main failure mode of the back bolt pull-out test is the fracture of the glass-ceramic plate and only part of the samples are cone-shaped failures, but the shear test failure modes are all back-bolted shear yield failure , In some cases, the glass-ceramic plate was damaged by partial prying, but the back bolt had yielded before the prying.

(4) Generally speaking, the shear failure load of the back bolt connection is not more than 0.8 times the tensile failure load.

According to the "Man-made Panel Curtain Wall Specification", the tensile and shear bearing capacity of the back bolt connection should be determined through experiments. The design value of the tensile bearing capacity is equal to the minimum value of the measured tensile failure force of the back bolt connection divided by the back bolt connection bearing capacity. The term coefficient is 2.15, and the design value of the shear capacity is not greater than 0.8 times the tensile capacity.

7 Artificial board curtain wall supporting structure design

7.1 Design of supporting member

The supporting structure of the man-made panel curtain wall is mainly steel, aluminum and other metal structures. The "Code" stipulates that the flexural strength, shear strength and stability of the cross-section of main supporting members such as beams and columns shall meet the following requirements:

1) Rolled or welded steel profile components should comply with the current national standard "Code for Design of Steel Structures" (GB50017);

2) Cold-formed thin-walled steel components should comply with the current national standard "Technical Specifications for Cold-formed Thin-walled Steel Structures" (GB50018);

3) Aluminum alloy profile components should comply with the current national standard "Aluminum Alloy Structural Design Code" (GB50429);

4) The flexural strength, shear strength and stability of the member section can also be analyzed and calculated by the finite element method.

7.2 Deflection control limits of beams and columns. The deflection limits of curtain wall beams and columns are to control the deformation of curtain wall panels under wind load. It has nothing to do with the materials of beams and columns. Refer to the regulations and regulations of relevant foreign codes. Engineering experience, the "Man-made Panel Curtain Wall Specification" uniformly stipulates the deflection control value of the curtain wall beam and column as: when the span is not greater than 4500mm, fd≤l/180; when the span is greater than 4500mm, fd≤l/250+7 d is the deflection of the beam or column (mm); l is the calculated span of the beam or column (mm), and the cantilever member can be selected to be twice the length (glass curtain wall, metal and stone curtain wall, and man-made panel curtain wall three specifications are unified and coordinated).

Figure 1 Schematic diagram of the axial tensile test of the back bolt connection assembly

Figure 2 Schematic diagram of the transverse shear test of the back bolt connection assembly

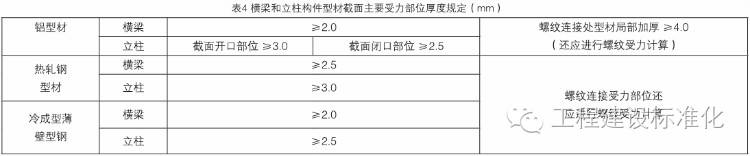

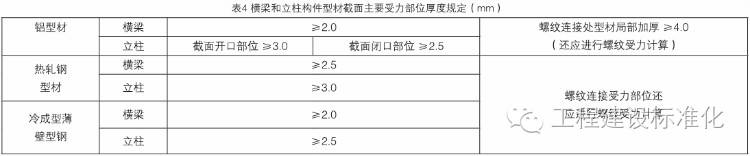

7.3 Control of section wall thickness of member profile

The section thickness of the supporting member profile is a technical and economic comprehensive index related to the safety of the curtain wall structure and the amount of material. According to the design specifications and engineering experience of steel structure and aluminum structure, see Table 4 in the "Technical Specifications for Man-made Panel Curtain Wall Engineering".

8 Conclusion

The formulation of the "Man-made Panel Curtain Wall Engineering Technical Code" is based on the six panel materials with different materials, structures and characteristics, starting from the research and testing of the required performance of the building curtain wall, and on the basis of compiling the product standards for the building curtain wall. Certain theoretical research and verification tests, referring to relevant domestic and foreign standards and specifications, summing up the practical experience of China's man-made panel curtain wall engineering in recent years, have newly developed six new types of engineering specifications for non-transparent panel curtain walls, from the definition of terms, material selection, Performance design and testing requirements, building structure and structure design, to processing and production, installation and construction, project acceptance, maintenance and repair, provide a comprehensive range for China's man-made panel curtain wall engineering to achieve advanced technology, safety, reliability, beauty and application, environmental protection and energy saving. The technical basis fills in the blanks in the technical specifications for China's new man-made panel curtain wall engineering. After review by the Ministry of Housing and Urban-Rural Development, the specifications have generally reached the international advanced level.

National Meteorological Administration Building (Trance Board Curtain Wall)

Beijing Hotel Phase II (Ceramic Panel Curtain Wall)

Beijing High Court (Porcelain Panel Curtain Wall)

Shanghai Nanyang International School (Cement Fiberboard Curtain Wall)

Foshan Global International Plaza (stone honeycomb panel curtain wall)

Inner Mongolia Expressway Company of Hohhot City (Curtain Wall of Glass-ceramics)

Feedback

Feedback