From the construction of the first production line to the commissioning of the second line, and then to the construction of the third and fourth lines, in just over four years, Sinoma (Yichang) Energy Conservation New Materials Co., Ltd. (hereinafter referred to as Sinoma Yichang) invested by China National Building Materials Group The scale has tripled and production capacity has quadrupled.

What is the driving force that drives Sinoma Yichang's rapid growth like fission? Recently, a reporter from "China Building Materials News" made a special trip to western Hubei to interview this "young" enterprise with the prefix "Chinese".

Starting from waste and environmental protection

Since the 18th National Congress of the Communist Party of China, my country has been unprecedented in its determination, strength, and effectiveness in promoting ecological environmental protection. A consensus has been formed across the country that "protecting the ecological environment means protecting productivity, and improving the ecological environment means developing productivity".

It is located in Dangyang City, the "Three Kingdoms Cultural City" not far from the Three Gorges of the Yangtze River in western Hubei. It has rich quartz sand mineral resources and is the largest float glass production base in Hubei. Local glass production companies produce a large amount of quartz sand tailings and waste sludge every year, which not only occupies land, but also seriously pollutes the local ecological environment.

Sinoma Yichang Chairman Xu Zheng said that it was precisely these quartz sand tailings that people regarded as "waste" that the company chose to settle in Dangyang. On the one hand, this can help digest the local quartz sand tailings, achieve energy saving, consumption reduction, and recycling; on the other hand, it can drive the transformation, development, and upgrading of the building materials industry in Dangyang City.

Xu Zheng told reporters that quartz sand tailings are actually "a resource that has been misplaced." It contains waste residues, tailings and tailings from the mining and screening of quartz mines, of which tailings account for the vast majority. The chemical composition of this kind of quartz tailings is mainly silica, and the impurities are mainly feldspar, clay, mica, iron minerals, etc. As long as reasonable development and scientific utilization, pollution can be eliminated, waste is turned into treasure, and the scope of mineral applications can be broadened. , Increase the added value of minerals, and have broad prospects for development.

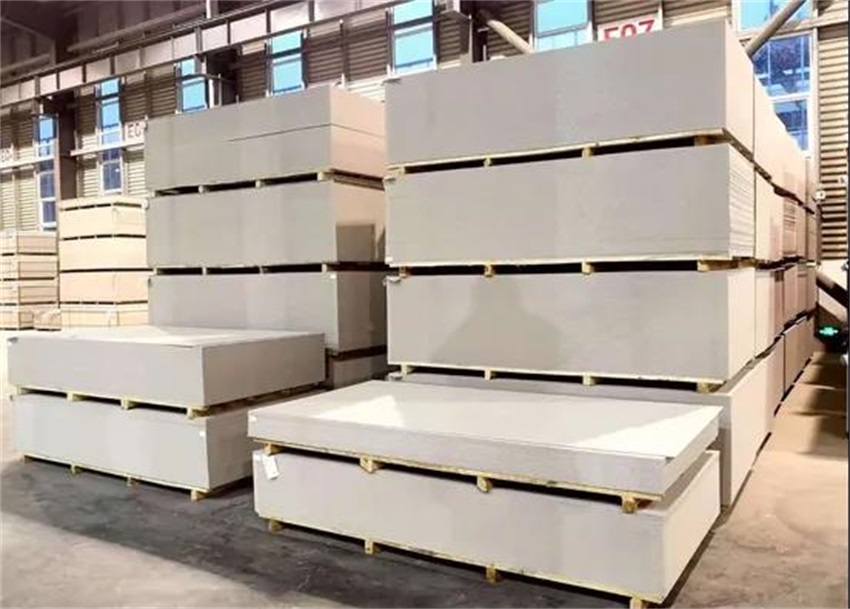

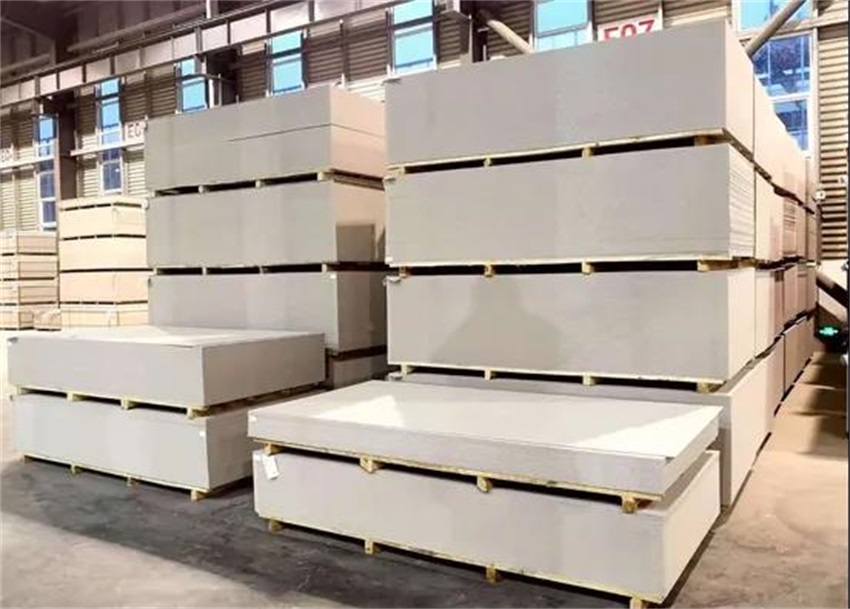

Sinoma Yichang is using the quartz sand tailings produced by local glass companies, with wood pulp fibers, ordinary Portland cement, slag, lime and other raw materials, and using a series of high-tech products to produce a "calcium silicate board" The green energy-saving wall material products, thus opening up a green development road of "turning waste into treasure, low-carbon nuggets". At present, the company can absorb 50,000 tons of quartz sand tailings every year, and produce 10 million square meters of high-end calcium silicate substrates and 1 million square meters of coated plates when it reaches full production. And next year, this set of data will double.

Xu Zheng said that it is the original intention of Sinoma Yichang to be committed to ecological and environmental protection. Low-carbon and energy-saving runs through the entire production process. The company not only helps the society solve environmental problems, but also pays more attention to its own environmental protection and energy saving. Since its establishment, Sinoma Yichang has faced up to difficulties in building energy conservation and other important and difficult tasks, courageously tackling tough problems, seizing development opportunities, and actively exploring and innovating. In 2019, the Bureau of Housing and Urban-Rural Development of Yichang City, Hubei Province awarded Sinoma Yichang the title of “Enterprise with Outstanding Contributions to Building Energy Conservation”.

Calcium silicate board is inseparable from high temperature and high pressure steam curing, and a large amount of heat energy is consumed in the production process to maintain normal temperature and pressure. After the plates are discharged from the kettle, a large amount of residual steam will be generated. The heat discharged from the condensed water and residual steam in the autoclave accounts for more than 40% of the total heat consumption; at the same time, noise pollution occurs when the residual steam is discharged from the autoclave, and the noise emission is as high as 125 decibel. In response to the country’s call for energy conservation and emission reduction and environmental noise emission requirements, Sinoma Yichang has improved its waste steam utilization system to recycle part of waste heat and waste steam resources to achieve zero emissions of waste steam, which not only eliminates "whitening" in the production process. The "dragon" phenomenon greatly reduces the impact of noise and odor on the surrounding environment, and also reduces production energy consumption by nearly 1/3.

focuses on prefabricated buildings

Sinoma Yichang is a new material company owned by Sinoma Energy Conservation Co., Ltd., a listed company controlled by China National Building Material Group Co., Ltd., a company directly under the State-owned Assets Supervision and Administration Commission of the State Council. It was registered and established in Dangyang City, Hubei Province in July 2015. It is controlled by Sinoma Energy Conservation (Wuhan) Co., Ltd., a new material business development platform for Sinoma Energy Conservation, and introduced a mixed-ownership enterprise with private capital and employee shareholding. In August 2016, Sinoma Yichang officially started the construction of the first phase of the project. In August 2017, an annual output of 5 million square meters of high-end calcium silicate substrate production line and an annual output of 1 million square meters of coated board and thermal insulation and decoration integrated board production line Completed and put into production. In December 2018, the second high-end calcium silicate substrate production line with an annual output of 5 million square meters was put into operation. In July 2020, the company's third and fourth high-end calcium silicate substrate production lines started construction, and it is expected to be completed and put into production in May 2021. By then, the company will have an annual production capacity of 2,000 square meters of high-end calcium silicate substrates and an annual output of 1 million square meters of coated panels and thermal insulation and decorative integrated panels, ranking first in Central China.

"These calcium silicate board substrates have reached Class A1 (non-combustible) fire rating. They have the characteristics of thermal insulation, anti-corrosion and mothproof, waterproof and moisture-proof, sound insulation and sound absorption, light weight and high strength, and are more energy-saving, environmentally friendly, earthquake-resistant, and impact-resistant than traditional boards It can be widely used in the fields of interior and exterior wall insulation decoration, suspended ceilings, billboards, cabin partitions, etc." Xu Zheng introduced that in recent years, with the continuous increase in the promotion of prefabricated buildings across the country, the demand for calcium silicate boards in the local market has increased. Whether it is used for composite lightweight wall panels, or directly used for interior and exterior wall insulation decoration, suspended ceilings, and floor linings, calcium silicate boards have become an important "role" in prefabricated house construction.

Soon after the first phase of the Sinoma Yichang project was put into production, the products quickly opened up sales channels, and most of the customers were relatively stable bulk customers. These large customers are the suppliers of prefabricated building demonstration projects, or light steel house manufacturers. Even with scattered customers or distributors, most of their product sales terminals are "landed" in prefabricated housing projects. "After the first two production lines were put into production, our company had very little inventory, so now we have to rush to expand the new line." said Shao Changgao, general manager of Sinoma Yichang. "From the perspective of development momentum, the prefabricated construction market is on an upward path. After the third and fourth lines are put into production next year, the company will have more voice and stronger market competitiveness in the field of calcium silicate boards and fabricated wall materials."

Innovation leads green development

The development of calcium silicate board has gone through two stages. The first stage is chrysotile calcium silicate board, in which asbestos fiber is added to enhance the flexural resistance of the board, but asbestos has been clearly identified as a first-degree carcinogen by the international medical community. Frequent exposure can cause lung cancer, pleura and peritoneum. Of mesothelioma and various malignant tumors, and long-term latency is not easy to be found. The second stage is a 100% asbestos-free ecological health board, which requires higher production equipment and technical processes, and naturally higher cost input. Therefore, at present, there are only a handful of domestic companies that have the ability to produce asbestos-free calcium silicate boards. Some small companies take risks in order to reduce production costs and still adopt the old path of asbestos technology that is harmful to the human body.

Xu Zheng said that a responsible company must be a company whose "body" and products are equally healthy. Today's era has entered an era of green and high-quality development, and companies must rely on a new concept of green and health throughout development. From the design, construction to operation of the production line, Sinoma Yichang always adheres to the asbestos-free product program to ensure that it provides a healthy and safe working environment for employees on the production line and provides consumers with green, environmentally friendly and safe products.

If idea innovation points out the direction for enterprise development, then scientific and technological innovation and management innovation are concrete supports to enhance the core competitiveness of the enterprise and ensure the efficient operation of the enterprise. Since its establishment, Sinoma Yichang has placed scientific and technological innovation at the top priority, and has established close cooperative relations with Wuhan University of Technology, Wuhan Engineering University, Wuhan Building Materials Industry Design and Research Institute and other universities and research institutes. Enterprise R&D investment has increased year by year. Last year alone, R&D expenses were invested 4.6 million yuan, accounting for 4.53% of the operating income that year. From January to October 2020, a total of 3.5052 million yuan has been invested in research and development, accounting for 5.27% of operating income. Up to now, the company has obtained 1 national invention patent and 8 utility model patents, and has been identified as a "high-tech enterprise". The company also cooperates with industry organizations such as the National Thermal Insulation and Decoration Integrated Board Association, Hubei Province Wall Material Industry Association, China Concrete Association Calcium Silicate Cement Board Branch and other industry organizations, actively participates in the preparation of relevant product standards, and researches and develops plank boards, full-body boards, etc. In the production process of new products, we try to replace some imported wood pulp with waste paper.

Respect the law of innovation and deeply promote management innovation. Sinoma Yichang actively carried out all-staff skills training and job optimization, and through enhanced management refinement, cost reduction and efficiency enhancement, single-line output increased by 5% over the same period last year, and capacity utilization reached 82%. Not long ago, at the 2020 China Concrete Exhibition and the China Concrete and Cement Products Industry Conference, Sinoma Yichang was awarded the “Top Ten National Calcium Silicate/Fiber Cement Board Enterprises in 2019”.

It is worth mentioning that during the new crown pneumonia epidemic this year, Sinoma Yichang innovatively established a “full-plane” epidemic prevention system integrating the company’s party organization + administration, departments, work sections, and teams. It focused on epidemic prevention and control on the one hand, and resumption of work on the other. Production, guaranteeing the “three-in-one synchronization online” of party building, epidemic prevention and control, and production resumption. The company also actively fulfills the social responsibility of a central enterprise, and has successively sent a number of party members and masses to sink the communities and villages where the company is located to participate in the front-line fight against the epidemic; at the critical moment of epidemic prevention and control, it donated to the Red Cross Society of Dangyang to support the local epidemic Prevention and control work.

Xu Zheng said that under the strategic guidance of China National Building Materials Group, Sinoma Yichang will be guided by technology and will pay more attention to the research and development and application of green building materials technology under the unified command of the industrial platform of Sinoma Energy Conservation Co., Ltd. and Sinoma Energy Conservation Wuhan Company. , Deepen reform, innovate and become self-reliant, fully implement the new concepts and goals of the building materials industry of "good for business and good for mankind", develop the calcium silicate board industry with high quality, and make greater contributions to my country's building energy conservation and ecologically livable construction.

Feedback

Feedback