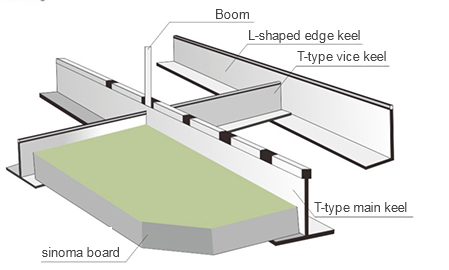

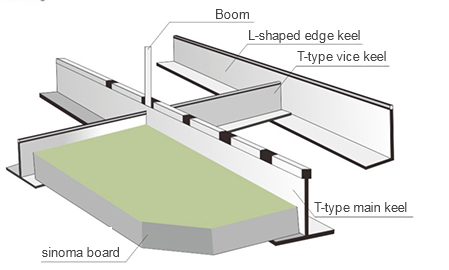

Ceiling series

Ceiling series

1. Determine the center distance of metal suspender with snapline.

2. Fix the edge keel on the walls around ceiling with the self-tapping screw.

3. Fix the T-type main keel with metal suspender, wherein the center distance of T-type main keel is 600mm or 610mm.

4. Insert T-type secondary keel into the main keel every 600mm or 610mm.

5. Place sinoma board on the T-type keel skeleton.

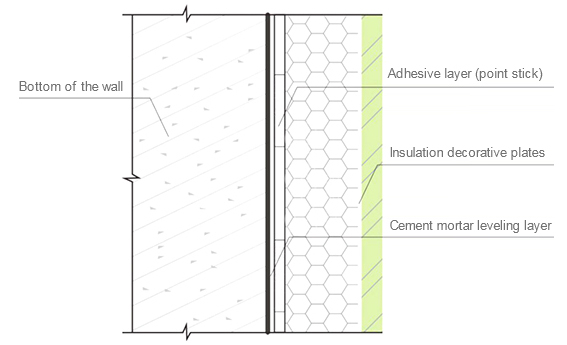

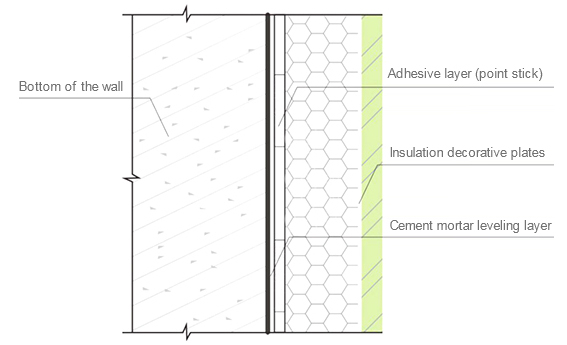

Wall bonding series

Wall bonding series

1. The cement mortar toweling course shall be solid, flat and free of hollowing; and the quality reaches Code for Construction Quality Acceptance of Building Decoration.

2. Prepare the binder dry powder and water proportionally, mix in mortar mixer for 3-5min, still for 5-10min, and use after mixing uniformly.

3. The insulating decoration board shall be horizontally paved along the horizontal direction according to the reserved typesetting position from top to down, the slab joint width shall be designed by typesetting, and the joint width shall be generally 6mm.

4. The binder shall be smeared on the back of insulating decoration board with point frame method, to guarantee that the bond area shall be more than 40%.

5. The deviation of flatness of sticking board shall be less than 3mm, and the height difference of adjacent boards shall not be more than 1mm. The slab joint shall be horizontal, flat and vertical, and the deviation shall be less than 1mm.

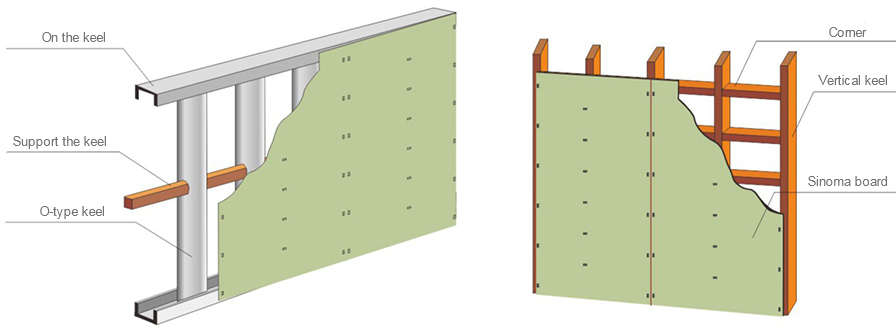

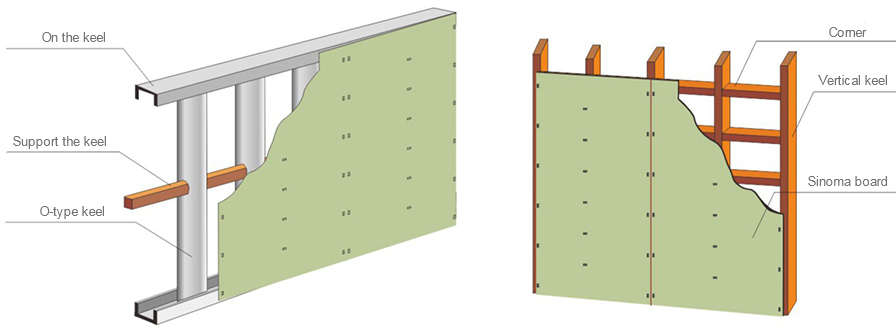

Light steel keel partition series

Light steel keel partition series

1. Cut the board to the required size (about 10mm shorter than the wall height)

2. Fix the board on the keel with self-tapping screw in the form of staggered joint. Generally, the self-tapping screw has a distance of about 200-250mm and shall be sunken into the board for 0.5mm.

3. Pay attention to reserve about 4mm expansion joint between plates

4. The blanking plate shall be fixed from the middle of the plate to its periphery, and the multipoint simultaneous operation cannot be carried out, so as to avoid the internal stress to enable the board to distort.

5. Before fixing and packaging the board, the glass wool or rock wool and others can be inserted into the cavity of keel skeleton according to the need to strengthen the sound insulation and fire protection effect.

Wall dry hanging series

Wall dry hanging series

1. Inspect the base course wall. The allowable deviation of flatness is 5mm, and the allowable deviation of perpendicularity of facade is 5mm.

2. Typeset, divide the mesh and snap the line according to the design requirement.

3. Drill and install the plastic expansion anchor according to the design typesetting, and connect the L-type angle code connecting piece and wall.

4. Connect the upper and lower strip connecting pieces and angle code, and install the insulation board after adjusting the perpendicularity.

5. Inject the weather-resistant sealant in the aluminium alloy groove when installing, clamp the aluminium alloy trim strip, uncover the protective film, and clean the board.

Ceiling series

Ceiling series

Wall bonding series

Wall bonding series

Light steel keel partition series

Light steel keel partition series

Wall dry hanging series

Wall dry hanging series

Feedback

Feedback